Best Practices for Extending the Life and Performance of Hot Water Steam Hose Stations, Throughout Your Plant

One of the most frequent questions SuperKlean receives from Plant & Factory Managers revolves around the difficulties they encounter when trying to clean or maintain Steam Hose Stations that are positioned around their plant or factory. One Plant Safety Manager recently contacted our distributor regarding growing problems they were having with over 60 steam and cold water units sold by one of our competitors. These units had been in operation in some cases just for a few years, and in other cases for over a decade. Their hot water steam station problems were multifaceted; employees were getting burned by gaseous steam leaking into hot water hoses that were bursting open, endangering operators. Another problem was that their existing units often had to be removed from the wall for maintenance, with costs ranging from $450 for replacement parts, all the way up to approximately $1,500 when labor was included. During the tour, we asked why they did not perform preventative maintenance periodically. The answers were very familiar … they could not afford to shut down a production line that was running every day, it was too complex, and finally, it was too expensive.

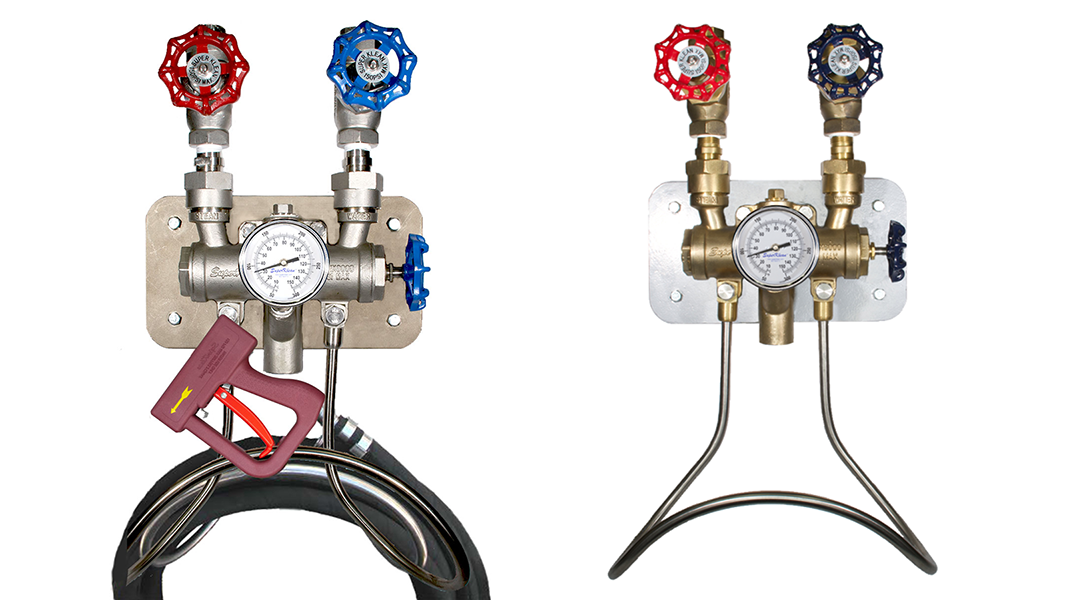

SuperKlean offers the much needed solution. Managers at these plants and factories often switch over to SuperKlean’s DuraMix 8000 Steam and Cold Steam Hose Stations throughout their entire operation. The #1 reason we find is the 8000’s ‘Ease of Maintenance’ and 3 year warranty. More than two decades ago, SuperKlean designed the DuraMix 8000 Series based around an innovative, ‘on-the-wall’ preventative maintenance capability that requires only 15 minutes, and remarkably, only a $2.50 replacement gasket. Our kit for steam hose station matintenance consists of a $2.50 gasket, and we provide 2 free gaskets in each 8000 box we ship!

Plant Maintenance Managers can have their teams watch SuperKlean’s short 4 minute Preventative Maintenance video, then perform the entire, simple maintenance procedure during a shift break or lunch.

SuperKlean found during our 30 year history of designing and selling exceptional Hot and Cold Water Hose Stations and Steam & Cold water mixing stations across the globe, that food, beverage, pharma, dairy, and countless other vertical markets depending on steam can often be very greasy places. This means the equipment used, especially Steam Hose Stations, needs to be constantly cleaned and well-maintained. We design and manufacture our hose stations, industrial hot water hoses, low flow nozzles, and entire line of washdown equipment to stand up to the harshest environments. SuperKlean understands that plants and factories across the country must keep their lines moving, so our superior washdown equipment saves you both time and money on maintenance.

SuperKlean’s technical staff can assist you in designing a maintenance plan that fits your specific plant’s requirements based on the washdown equipment you have. Often, Plant Maintenance Managers will do preventative maintenance on steam host stations every 6 months, or 12 months, with a schedule that matches each specific area where a SuperKlean steam hose station is being used. In many cases, frequency of preventative maintenance is also based on the type of local water being used (highly mineralized versus normal water) or the type and age of piping throughout the factory or plant.

With SuperKlean’s easy, fast and low cost preventative maintenance, your steam hose stations can last for many years. Performing quick and easy preventative maintenance is a guaranteed way to washdown success.

For more input on how SuperKlean’s DuraMix 8000 Series can help your operation, please call us anytime at 1-800-769-9173, or visit our website at www.superklean.com/shop/mixing-stations . We are here to provide you with the best and fastest service and advice available!