Due to the expense of washdown equipment and industrial hoses in particular, many want to do whatever they can to ensure that their products will last as long as they can. The main way to do so is through internal hose guards.

Plants and factories across the world often use very hot water when doing periodic washdown of equipment and floors in industrial food, beverage, pharmaceutical and dozens of other washdown applications. In fact, hot water often ranges between 140 – 180 degrees, and sometimes reaches 190 degrees Fahrenheit or more. When most types of hot water washdown hoses are super-heated to these temperatures they become quite soft and pliable. This causes hoses to be highly susceptible to breakage and tearing.

Industrial hot water hoses are very expensive and are used in lengths varying from 25 feet, up to 100 feet or more. Hose costs to plants and factories can vary from a few hundred dollars up to $1,000 or more for premium, longer length hoses. This is a significant investment for factories and plants, especially since hose are required to stand up to heavy use and need to be replaced often. Studies have shown the weakest points of industrial hoses are on the ends, where the sharp edges of the internal hose barbs that connect to the hose are specifically engineered to hold hoses securely, with sharp, exposed edges.

Factory washdown employees, sometimes several times a day, will uncurl large and very heavy hot water hoses off industrial hose racks, then drag these water-filled hoses across factory and plant floors to reach all equipment and floor areas that needs to be cleaned. At no fault of factory workers, hoses often need to be pulled or ‘yanked’ with great force, stressing the already softened hot water hoses directly where the hose rubs against the bottom edge of the hose barb, internally inside the hose. This happens both at the connection to the industrial water nozzle, or where the hose is connected to the wall. This is where hot water washdown hose failure often occurs.

SuperKlean Washdown Products has been selling internal hose guards for over 10 years. We have been closely monitoring internal hose guard trends that come from the best hose distributors and informed plant safety and quality managers who, more and more, are demanding hose guards be included in their bids. The word is spreading – using top quality hose guards can significantly extend the life of your hot water industrial hoses, sometimes 3 times or more. Here are the real numbers – less than a $100 upfront internal hose guard investment can save many $100’s of dollars over the expected life of a hose!

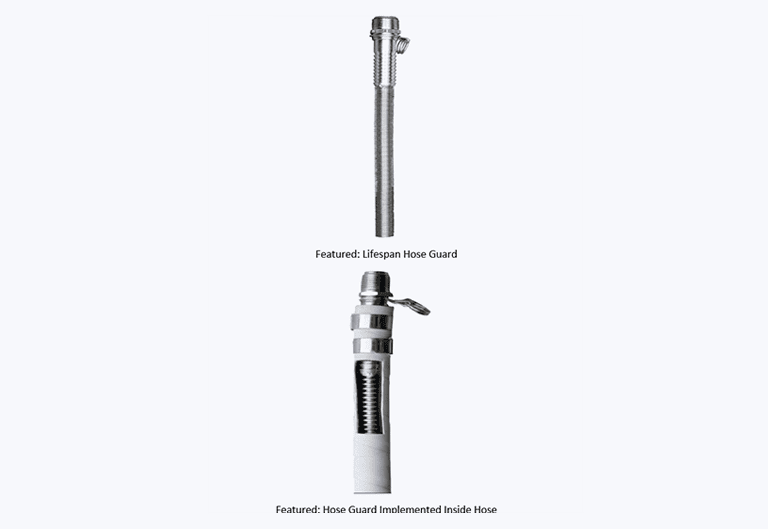

In 2019 SuperKlean formally announced immediate availability of a new, extensive line of ‘LifeSpan’ Hose Guards that provide the most effective way to reduce hot water hose breakage, due to exposed hose barbs or shanks.

These low-cost internal hose guards are available on most of SuperKlean’s famous line of hose swivel adapters and hose swivel fittings that have been a favorite in the worldwide hot water washdown industry for decades. All SuperKlean fittings and adapters, including SuperKlean LifeSpan Hose Guard Adapters, feature SuperKlean’s exclusive 2 ¼ inch long hose barbs and unibody lock O-ring fitting that insure these swivel fittings never come apart.