Resources

- Click Here For Technical Drawings

- Click Here For Installation Manual

- Click Here For Duramix 8000 Parts List

- Please Click Here to view the SuperKlean Duramix 8000GM series Steam & Cold Water Mixing Stations specification sheet and parts list

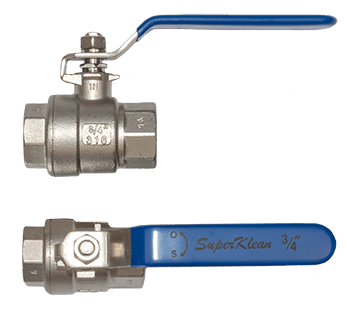

3/4″ Ball Valves

- Bronze and stainless steel constructions, all ball valves are corrosion resistant.

- Maximum valve pressure rating is 600 PSI WOG (Water, Oil, and Gas).

- All ball valves have a PTFE stem packing which helps prevent leakage around the stems of valves.

- Secured with chrome plated seats, which ensure durability and reliability.

SuperKIean’s new 3/4″ industrial ball valves give users the ability to shut down water/steam supply lines with a single pull of a lever. Its bronze or stainless steel construction enables this ball valve to be used with either water, oil, gas, or steam. All stainless steel components are 300 series stainless steel to prevent corrosion. Our 3/4 hot water ball valve is the most widely used ball valve in the industry. The stainless steel handle with a plastic dip, which not only offers an easy and secure grip, but also protects the user for high temperature transfer to the lever.

For more information on SuperKlean 3/4 bronze ball valves, 3/4 stainless steel ball valves, or other wash down products, please contact us.

- SPECIFICATIONS

- APPLICATIONS

- ADDITIONAL INFORMATION

Inlet / Outlet Diameter: 3/4″

NPT Ball Valve Body: Bronze or Stainless Steel

Lever and Grip: Stainless Steel with Vinyl

Stem Packing: PTFE

Stem Bearing: PTFE

Ball: Chrome Plated

Seats: PTFE

Retainer: Brass or Stainless Steel

Gland Nut: Brass or Stainless Steel

Stem: Brass or Stainless Steel

Lever Nut: Stainless Steel

Body Seal: PTFE

Weight: 1.28 Lbs.

Pressure Rating: 600 PSI WOG ·150 PSI STEAM

| BALL VALVES | |

| Description | PART # |

3/4” ball valve, bronze, blue lever | BALL VALVE-BLUE |

3/4” ball valve, bronze , red lever | BALL VALVE-RED |

3/4” ball valve, Stainless Steel, blue lever | BALL VALVE-SSBLUE |

3/4” ball valve, Stainless Steel, red lever | BALL VALVE-SSRED |

The following industries are just a few of the applications that regularly use 3/4 ball valves:

- Chemical Processing Plants

- Oil Refineries

- Wineries/Breweries

Resources

- Click Here For Technical Drawings

- Click Here For Installation Manual

- Click Here For Duramix 8000 Parts List

- Please Click Here to view the SuperKlean Duramix 8000GM series Steam & Cold Water Mixing Stations specification sheet and parts list