Hot and cold water mixing stations are one of the most important pieces of washdown equipment in the industrial world. Mixing stations do exactly that; they mix hot water and cold water to result in the precise water temperature needed for FDA approved plant and factory sanitation. Mixing units are typically mounted on walls or posts and directly connected to hot and cold water pipes in factories. Hose mixing units are made of stainless steel or brass (stainless steel is preferred in highly corrosive environments).

In certain large plants and factories that make products requiring consistent high temperature and high volumes of hot water, steam & cold water mixing units are preferred over hot & cold water units. Steam flows through pipes in these plants directly to sophisticated mixing stations and then combines with cold water within the mixing station’s main chamber. A control valve allows the hot water temperature to be adjusted, commonly set at 185 degrees Fahrenheit or higher. The hot water is then channeled by the mixing unit to a special industrial hose and high-performance nozzle used to clean and sanitize floors and equipment.

Hot water created by steam is extremely proficient in delivering cost-effective and large amounts of continuous hot water to kill bacteria and provide ultimate factory and plant sanitation.

Wineries, breweries, and some beverage and food operations that do not need to generate significant amounts of hot water at high sustained temperatures often use hot and cold water mixing stations. For these types of mixing stations or hose mixing units, hot water is often generated using natural gas boilers. Hot water is brought into the mixing station through one pipe and cold water through another, then mixed in a special chamber to provide the desired water temperature into the hose and heavy duty industrial nozzle.

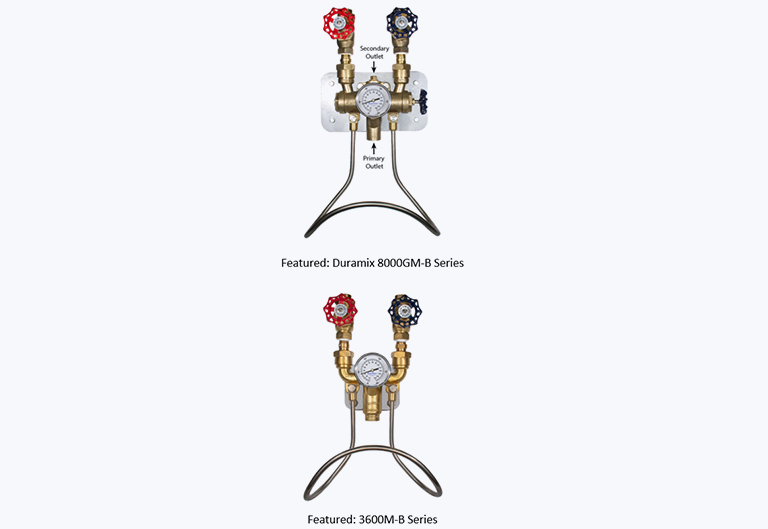

Different companies name their washdown products in slightly different ways. Mixing stations are sometimes referred to as mixing valves, mixing units, or hose mixing units. For some companies, steam water mixing station and steam water mixing valve represent the same type of product. For other companies, mixing valve refers to the mixing chamber only, and does not include globe valves, a temperature gauge, a hose rack and other necessary parts.

For 30 years, SuperKlean Washdown Products has been manufacturing a full line of both steam mixing stations and hot and cold water mixing stations that include all the necessary parts for installation right out of the box. SuperKlean is also the only company that offers a unique secondary port on its steam mixing stations, allowing customers to run a second line of hot water from this original unit. SuperKlean mixing stations are the safest on the market, never leaking harmful steam or hot water. Please visit our Product page to view all SuperKlean mixing stations.