Resources

- Click Here For Technical Drawings

- Click Here For Installation Manual

- Click Here For Duramix 8000 Parts List

- Please Click Here to view the SuperKlean Duramix 8000GM series Steam & Cold Water Mixing Stations specification sheet and parts list

Steam Trap

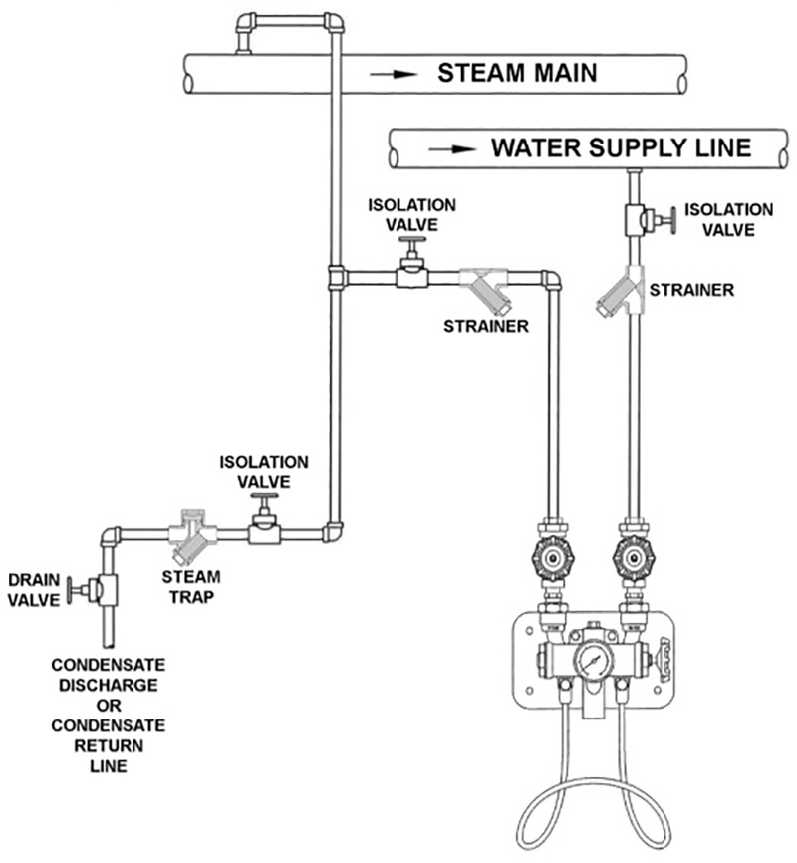

- Steam Traps / Steam Strainers play important roles in keeping steam lines connected to SuperKlean DuraMix 8000 mixers clean and pristine.

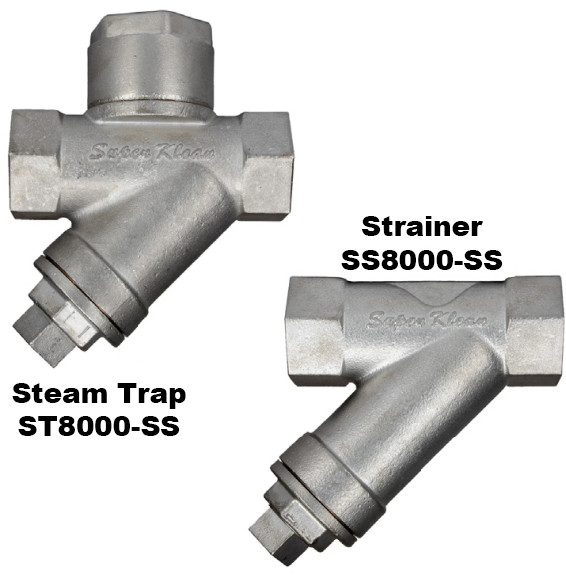

- 3/4″ disc-type steam trap. Stainless steel.

- SuperKlean Steam Traps and Strainers are designed to keep steam pure and contaminate-free.

- Thermodynamic steam trap – simple design, efficient and reliable

- Integral strainer and replaceable seat for easy maintenance

- SPECIFICATIONS

- APPLICATIONS

- ADDITIONAL INFORMATION

Inlet / Outlet diameter: 3/4” NPT

Body: 304 Stainless Steel

Gaskets: Copper

Screen: 20 mesh

Blow down valve opening: 1/2” NPT

Maximum steam pressure (saturated only): 600 PSI

Maximum water pressure: 600 PSI

Maximum steam temperature: 800°F (427°C)

Weight: 1.5 lbs (steam trap) or 1 lb (strainer)

| STEAM TRAP | |

| Description | PART # |

| 3/4” disc type steam trap. Includes internal strainer. 304 Stainless Steel | ST8000-SS |

| STRAINER | |

| 3/4” Y-type strainer. 304 Stainless S | SS8000-SS |

Boost Efficiency & Hygiene with SuperKlean Steam Traps: The Industry's Best Choice

Supercharge your industrial operations with SuperKlean, the leading name in high-performance steam traps. Our cutting-edge technology seamlessly integrates with our renowned DuraMix Steam Hose Stations, widely recognized as the gold standard in washdown applications. Designed with a focus on efficiency and hygiene, SuperKlean steam traps deliver a cost-effective solution for boosting performance across diverse industries.

Unleash the Power of Steam in Every Industry:

Industrial Cleaning & Sanitation: Elevate your hygiene standards with SuperKlean's contaminant-free steam. Ensure a sterile environment in food processing, beverage production, and animal slaughter plants, exceeding the most stringent regulations.

Dairy, Cheese, & Confectionery Production: Maintain the purity of your steam and guarantee the highest product quality. SuperKlean safeguards your delicate processes in the dairy, cheese, and confectionery industries, ensuring every batch meets your exacting standards.

Pharmaceutical & Perfumery Industries: Achieve ultra-clean steam for your sensitive processes with SuperKlean's precision engineering. Our traps guarantee impurity-free steam, safeguarding product integrity and upholding the rigorous standards of the pharmaceutical and perfumery sectors.

Aging Industrial Facilities: Breathe new life into your aging plant with SuperKlean's revitalizing steam. Our traps combat internal pipe degradation, extending the operational life of your facility without costly retrofits.

New & Retrofitted Facilities: Proactively safeguard your steam purity from the start. SuperKlean traps efficiently remove installation residue in new piping systems, ensuring optimal performance from day one.

Water Quality Management: Tackle water quality concerns with SuperKlean's dual-action traps and strainers. Filter out particulates from aging cold water pipes, ensuring clean and pure water for your industrial processes.

Comprehensive Facility Maintenance: Integrate SuperKlean into your maintenance strategy for a safer, more efficient operation. Our traps contribute to top-notch steam and water quality, minimizing downtime and enhancing overall facility safety.

Energy & Resource Conservation: Embrace sustainability with SuperKlean's energy-saving design. Our traps minimize steam loss, reducing your facility's energy footprint and aligning with your environmental goals.

SuperKlean steam traps are versatile, essential components for various industries. From hygiene-critical environments to resource-conscious facilities, they ensure the purity and efficiency of your steam, contributing to product quality, facility maintenance, and environmental sustainability. Whether you're equipping a brand-new facility, revitalizing an aging plant, or operating in an industry with stringent cleanliness standards, SuperKlean steam traps provide a reliable and effective solution.

Contact SuperKlean today and experience the difference for yourself.

SuperKlean: Unlocking Efficiency and Hygiene with Verified Results

Problem & Solution:

Industrial facilities face the constant struggle to balance hygiene, efficiency, and cost-effectiveness. SuperKlean, a leader in steam traps, cold water strainers, and DuraMix hot water washdown stations, offers proven solutions to achieve all three. Our products help you:

- Maintain stringent hygiene standards: SuperKlean's contaminant-free steam and pre-filtered water ensure flawless sanitation, minimizing the risk of product recalls and ensuring a safe working environment.

- Boost efficiency and productivity: SuperKlean's thermodynamic steam traps minimize steam loss, leading to increased energy savings and optimized process times. Our cold water strainers also reduce downtime by preventing blockages.

- Extend equipment lifespan: SuperKlean's traps combat pipe degradation in both new and aging facilities, extending equipment life and reducing the need for costly retrofits.

Industry-Specific Benefits:

- Food & Beverage: SuperKlean's technology helps food manufacturers meet the most rigorous hygiene regulations, contributing to superior product quality and taste.

- Pharmaceuticals & Perfumery: Our ultra-clean steam and water solutions meet the high standards of these industries, ensuring product integrity and safety.

- Dairy & Confectionery: SuperKlean's products help you maintain consistent product quality and reduce downtime, leading to increased production capacity and profitability.

Ready to Supercharge Your Facility?

SuperKlean offers a comprehensive range of solutions to address your specific needs. We offer:

- Expert consultation: Get personalized recommendations for your industry and equipment.

- Downloadable resources: Access case studies, white papers, and installation guides.

- Free quotes: Request a customized quote for your specific requirements.

Resources

- Click Here For Technical Drawings

- Click Here For Installation Manual

- Click Here For Duramix 8000 Parts List

- Please Click Here to view the SuperKlean Duramix 8000GM series Steam & Cold Water Mixing Stations specification sheet and parts list